T: +86-180-67981129

E:sales@pino-electric.com

E:sales@pino-electric.com

Makou Industrial Park, Yongxiu County, Jiujiang city, Jiangxi Province, China

Views: 0 Author: Site Editor Publish Time: 2025-08-14 Origin: Site

An oil filled transformer uses special oil to keep its parts cool and safe. It is important in power systems because it helps move electricity between different voltages. Most power grids use this type since it can handle big loads and keeps things at safe temperatures.

Company Name | Estimated Market Share (%) |

|---|---|

Siemens Energy | 18–22% |

ABB Ltd. (Hitachi Energy) | 16–20% |

General Electric Company | 12–16% |

Schneider Electric SE | 8–12% |

Toshiba Energy Systems | 6–9% |

Other Companies (combined) | 25–30% |

This table shows oil-filled transformers are used in almost all power transformers around the world.

Oil in an oil filled transformer works as a coolant and an insulator.

It helps high efficiency oil filled power transformers by stopping electrical problems and moving heat away fast.

It allows safe, small, and strong designs for today's energy needs.

Oil-filled transformers use special oil to keep cool and protect their parts. This helps them handle high voltage and heavy loads safely.

There are different types for homes, factories, and power grids. Each type is made for certain voltage and power needs.

Regular oil testing and maintenance stop leaks, fires, and electrical problems. This keeps transformers working well for a long time.

Oil-filled transformers work better than dry-type transformers. They are good for outdoor use but need careful safety checks.

Using eco-friendly oils and proper spill control helps the environment. It also keeps transformers safe and working well.

An oil filled transformer changes voltage in electric systems. It uses special oil to keep its parts cool and safe. The oil also stops electrical problems from happening. This type of transformer can handle high voltages and lots of power. You will see it in power plants, substations, and factories. People pick this kind when they need a high efficiency oil filled power transformer for tough work.

Oil-filled transformers use oil to cool and insulate. The oil stays inside a strong steel tank. This helps the transformer stay cool better than other types. It also lets the transformer work safely with heavy loads. Since the oil can burn, most oil filled transformers are kept outside. They need regular checks to make sure the oil is clean and works well.

Note: Oil-immersed transformer is another name for oil filled transformer. Both words mean the same thing.

An oil filled transformer has many important parts. Each part helps the transformer work well.

Core: Made from special steel or alloy. These materials help the core carry magnetic energy with little loss.

Windings: Made from copper or aluminum. Copper is strong and conducts electricity very well. Aluminum is lighter but still works well.

Oil: Cools and insulates the transformer. It moves heat away from the core and windings.

Tank: A steel tank holds the oil and all the parts inside.

Bushings: Porcelain bushings connect the transformer to wires outside.

Radiators or Heat Sinks: These help the oil get rid of heat into the air.

Component | Common Materials | Purpose |

|---|---|---|

Core | Silicon steel, amorphous alloy | Carries magnetic flux, reduces losses |

Windings | Copper, aluminum | Conducts electricity |

Oil | Mineral or synthetic oil | Cools and insulates |

Tank | Welded steel | Holds oil and parts, protects from damage |

Bushings | Porcelain | Connects to external circuits |

Oil filled transformers are bigger and heavier than dry-type transformers. They need more care, but they can handle more power and higher voltages. This makes them the best choice for big jobs in the power industry.

Oil filled transformers use oil for cooling and insulation. The oil takes heat from the core and windings. It moves the heat to radiators or heat exchangers. This keeps the transformer safe and working well. The oil also stops electricity from jumping between parts inside the tank.

Tip: Check the oil often to keep cooling and insulation strong.

The table below lists ways oil filled transformers cool down:

Cooling Method | Description | Cooling Mediums Involved | Typical Application/Notes |

|---|---|---|---|

Natural Oil Air Natural (ONAN) | Oil moves by itself; heat goes to air naturally | Oil (natural), Air (natural) | Used for smaller transformers (<30 MVA) |

Natural Oil Air Forced (ONAF) | Oil moves by itself; fans blow air on radiators | Oil (natural), Air (forced) | Used when more cooling is needed |

Forced Oil Air Forced (OFAF) | Pumps push oil; fans blow air on radiators | Oil (forced), Air (forced) | Used for big transformers needing strong cooling |

Forced Oil Water Forced (ONWF) | Pumps push oil; water cools oil in heat exchangers | Oil (forced), Water (forced) | Used for very large transformers (>101 kV) |

Cooling keeps oil temperature safe in oil filled transformers. Most have a top oil temperature limit of 85°C. If it gets too hot, an alarm sounds. The highest cutoff temperature is 95°C to stop damage. Outdoor transformers work in temperatures from -25°C to 40°C. Indoor ones work from -5°C to 40°C. These limits protect the oil and help transformers last longer.

Transformer oil has high dielectric strength. It stops electricity from breaking down inside the tank. High breakdown voltage means the insulation stays strong and safe.

An oil filled transformer changes voltage in power systems. It has a steel core and copper or aluminum windings. Electricity flows through the windings and makes heat. The oil takes this heat and moves it to radiators or heat exchangers. Fans or pumps may help move oil and air for better cooling.

The insulation keeps the core and windings safe from electrical problems. The oil's high dielectric strength stops unwanted electricity from jumping. It also helps reduce shaking and keeps moving parts smooth.

Operators watch oil temperature and quality. They look for signs of old or dirty oil. Keeping oil clean and at the right temperature helps the transformer work safely and last longer.

Oil filled transformers use oil for cooling and insulation.

Radiators, fans, and pumps help remove heat faster.

Regular oil tests keep insulation strong and operation safe.

Oil filled transformers help deliver power in grids, factories, and buildings. Their design lets them handle heavy loads and high voltages.

Oil filled transformer types do different jobs in power systems. Each type has its own use and special features. The main groups are distribution transformers, power transformers, and special models.

Distribution transformers help move power to homes and businesses. They lower high voltage from big lines to safer levels. Most oil filled distribution transformer units work from 110 V to 11 kV. Their power ratings are less than 200 MVA. These transformers are close to where people use electricity. They make sure power is safe and easy to use.

Used in homes

Found in stores and offices

Help small factories

Note: Distribution transformers are near users and handle smaller loads.

Power transformers work with high voltage lines. They run at voltages from 33 kV up to 400 kV or more. Their power ratings are above 200 MVA. These oil filled transformer units move lots of electricity far away. Utilities put them in substations to link power plants to the grid.

Transformer Type | Voltage Range (kV) | Power Rating (MVA) |

|---|---|---|

Power Transformer | 33 kV – 400 kV or higher | Above 200 MVA |

Distribution Transformer | 110 V – 11 kV | Below 200 MVA |

Power transformers are important for power networks. They keep voltage steady and service strong.

Some oil filled transformer models do special jobs. These include:

Instrument Transformers: Check current or voltage for safety and control.

Auto-transformers: Use one winding for both sides to save space.

Phase-shifting Transformers: Change how power moves between generators.

Rectifier Transformers: Change AC to DC for things like charging batteries.

Tip: Special oil filled transformer units fix hard problems in power and industry.

The oil filled power transformer market has many designs. Each type is made for a certain job in power or industry. Picking the right one keeps power safe, strong, and reliable.

Oil filled transformers are very important in factories and big businesses. They help move high voltage power from power plants to where it is needed. Factories use these transformers to lower the voltage for big machines. Smelting plants and factories use them to run motors and arc furnaces safely. The oil keeps them cool and stops them from getting too hot. This lets them work with medium and high voltages. People pick oil filled transformers because they are reliable and can be used in many ways.

Some common uses in industry:

Power plants

Substations that lower voltage

Power networks

Big factories

Smelting plants

Oil filled transformers keep machines safe and make sure power keeps moving in hard places.

Utility companies use oil filled transformers to keep power moving safely. Big transformers help move high voltage power and keep the grid working well. Cities that are growing and new energy projects need better transformers. Companies make new transformers to save money and work better. Smart transformers help grids use power from solar and wind. These have special systems and sensors to help the grid change when needed.

Aspect | Details |

|---|---|

Grid Modernization | Utilities use oil filled transformers to make grids stronger. |

Transformer Types | Two-winding and auto transformers help keep things safe and efficient. |

Market Investment | In 2023, $7.5 billion was spent on U.S. line transformers. |

Renewable Integration | Smart transformers help with solar and wind power. |

Urban and Industrial Use | Auto transformers are good for cities and factories. |

Future Outlook | The market may reach $22 billion by 2034. |

Oil filled transformers keep important equipment safe and help protect the environment. They help utility companies give steady power to homes, stores, and factories.

Oil filled transformers are used in offices, stores, and homes. They cost less than dry-type transformers and cool better. People use them for high voltage power without limits. They can be used as power or distribution transformers. They work well outside and can be recycled. Checking them often keeps them safe and working for a long time.

Some benefits in homes and businesses:

Lower price

Better cooling

Can handle high voltage

Many uses

Good for the environment

Lasts longer

Works well

Stays steady when loads change

Keeps out water and dust

Special oils like FR3 and mineral oil make them safer from fire and help them last longer. Oil filled transformers help move power in tough places. They keep homes and businesses safe and powered.

Oil filled transformer and dry-type transformer are not the same. Oil filled transformer uses oil to cool and insulate. Dry-type transformer uses air and solid materials instead. Oil filled transformer is better for high voltage and outdoor places. Dry-type transformer is good for inside buildings and lower voltages.

Transformer Type | Cooling & Insulation Medium | Efficiency Level |

|---|---|---|

Oil-Filled | Oil (insulating and cooling) | Higher efficiency due to better heat dissipation |

Dry-Type | Air cooling and solid insulation | Lower efficiency, limited voltage rating, prone to overheating |

Oil filled transformer can handle more voltage and bigger loads. Dry-type transformer is best for small jobs and indoor use.

Oil filled transformer and dry-type transformer both have good and bad points.

Oil filled transformer:

Works with high voltage and heavy loads

Smaller and lighter than dry-type transformer

Can last up to 35 years

Needs oil checks and fire safety steps

Oil leaks can hurt the environment

Dry-type transformer:

Safer for inside use, less fire danger

Easier to put in and take care of

Costs more at first

Bigger and heavier

Lasts up to 25 years

Tip: Oil filled transformer is more efficient, but dry-type transformer is easier to care for and safer inside.

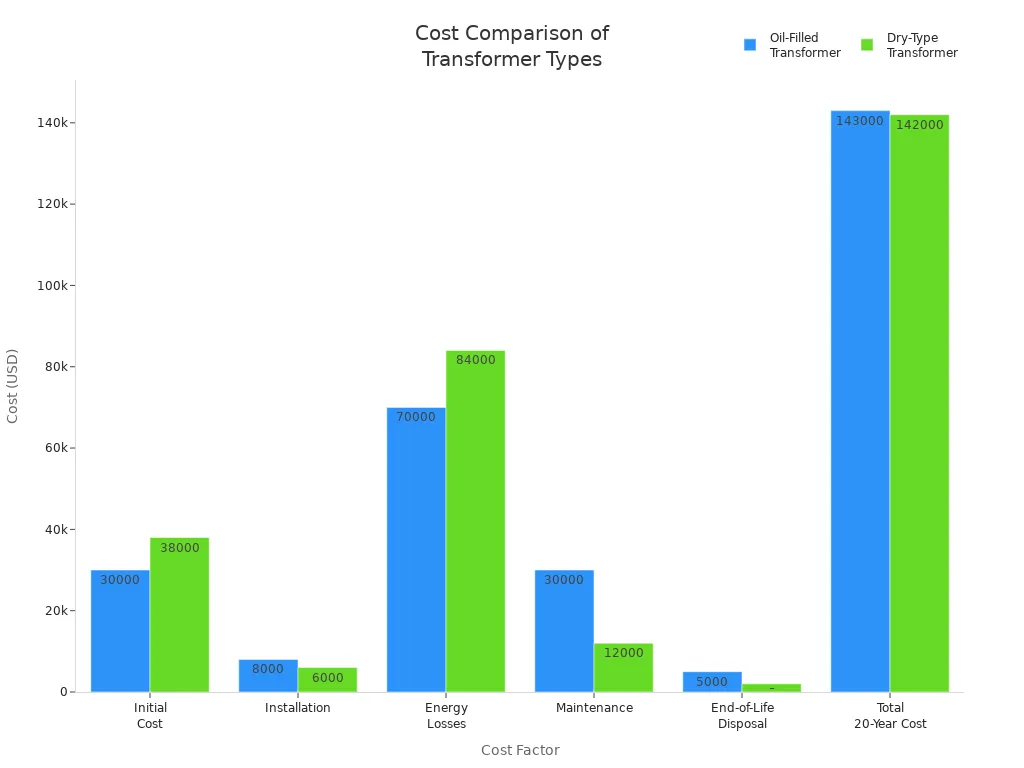

Cost Aspect | Oil-Filled Transformers | Dry-Type Transformers |

|---|---|---|

Initial Purchase Price | Lower upfront cost | Higher upfront cost |

Maintenance Costs | Higher due to oil testing and fire safety | Lower, mainly cleaning and inspection |

Repair Complexity | More complex and costly | Simpler and less expensive |

Environmental Impact | Risk of oil leaks | No risk of fluid leaks |

Installation Space | Needs more space for cooling and containment | Can be placed closer to loads |

Pick oil filled transformer or dry-type transformer based on where you need it, how much voltage, and your budget. Oil filled transformer is best for outside, high voltage, and when you need high efficiency oil filled power transformer. Dry-type transformer is better for inside, like schools and hospitals, where fire safety is very important.

Factor | Oil-Filled Transformer | Dry-Type Transformer |

|---|---|---|

Location | Best for outdoor spaces; risk of oil spills and fire | Best for indoor spaces; less flammable |

Operational Life | 25-35 years | 15-25 years |

Physical Footprint | Smaller size, lighter | Larger and heavier |

Efficiency | Higher efficiency, lower losses | Lower efficiency, prone to overheating |

Voltage Capability | Handles high voltage (up to 1000 kV) | Handles low to medium voltage (up to 35 kV) |

Costs | Lower initial and long-term costs | Higher initial cost |

Note: Oil filled transformer is best for outside, high voltage, and tough jobs. Dry-type transformer is safer for inside and easier to take care of.

Oil filled transformer safety means stopping fires and leaks. Leaks can start at gaskets, flanges, radiator fins, valves, bushings, or probe connections. Bushings and butterfly valves can get weak if gaskets loosen or bolts get old. Rust can hurt welds and seals, especially if water or air gets in. If you skip yearly checks, probe connections can get loose and leak. Finding leaks early stops fires, pollution, and big repair bills.

Fires can start if oil leaks and makes a pool or spray. Problems like lightning, too much power, or bad design can cause overheating, explosions, or fires. Inside heat can break down mineral oil and make dangerous gases like hydrogen and methane. Tank explosions can throw burning oil and heat at other machines. Oil fires can get as hot as 960 to 1200 °C and burn for hours. In 2014, a transformer blew up in a Turkish coal mine and killed over 200 people. This shows how risky these fires are.

Leak-Prone Parts | Fire Risk Factors |

|---|---|

Gaskets, bushings | Oil leaks, overheating |

Flanges, valves | Electrical faults |

Radiator fins, welds | Gas buildup, explosions |

Testing oil often keeps oil filled transformers safe and working well. Oil gets old and takes in water, so it loses its power to cool and insulate. Workers test oil in labs or on-site using ASTM rules. They check how much voltage the oil can handle, its color, water in it, and acid level. They also look for gases from problems like sparks or too much heat. Other tests check how well the oil resists electricity, if it has special chemicals, and if the insulation is healthy.

Test Name | What It Shows |

|---|---|

Color | Aging or contamination |

Dielectric Breakdown | Moisture or contamination |

Water Content | Moisture level in oil |

Acid Number | Oxidation and acid buildup |

Dissolved Gas Analysis | Faults like overheating or arcing |

Furanic Compounds | Paper insulation condition |

Doing regular checks helps oil filled transformers last longer. Every day, check oil and winding temperatures, oil levels, and how much power is used. Each week or month, look for leaks, check bushings, and clean extra circuits. Once a year, test cooling systems, clean bushings, and check relays and wires. Every 3-5 years, look for leaks near the pressure relief tank.

Maintenance Checklist:

Check oil level and temperature every day

Look at bushings and gaskets each month

Test oil for water and acid once a year

Clean and tighten wire connections

Listen and feel for odd noise or heat

Rules like NFPA 70 and EPA SPCC say you need safe vaults, spill plans, and ways to catch leaks. These rules keep workers, machines, and nature safe.

Oil spills from transformers can hurt nature in many ways. They make soil and water dirty. They also pollute the air and can start fires. Chemicals in transformer oil can poison plants and animals if they get out. Checking transformers often and storing them right helps stop leaks.

Tip: Always look for leaks and have spill kits ready for emergencies.

Environmental risks from oil spills include:

Dirty soil and groundwater

Rivers and lakes get polluted

Bad fumes and gases go into the air

Fires and explosions can happen

Dangerous chemicals harm animals and plants

Containment methods help keep people and nature safe. Companies use berms, dikes, and special barriers to stop oil from spreading. Oil-water separators clean dirty water before it leaves the area. Spill kits with pads and safety gear help workers clean up fast.

Containment Method | Purpose |

|---|---|

Berms and dikes | Stop oil from moving |

Secondary containment | Catch leaks under transformers |

Oil-water separators | Clean water before it leaves |

Spill kits | Clean up small spills quickly |

Full containment systems use liners and walls to keep oil away from rainwater. These systems help companies follow rules like SPCC and SWPPP. This keeps oil out of rivers and lakes.

Transformer oils are changing to help the earth. Natural esters from plants like rapeseed and sunflower break down fast and are not toxic. Synthetic esters are also safer and break down, but they cost more and are harder to recycle. Both types have high flash points, so they are safer than mineral oils.

Eco-friendly oils help stop pollution and lower fire risk.

New transformer oils have special additives to work better and last longer. Nanotechnology puts tiny particles in the oil to help with cooling and insulation. Rules from IEEE, ASTM, and IEC tell companies how to use safer oils. Using eco-friendly oils helps make power grids better and lowers harm to the planet.

Key features of eco-friendly transformer oils:

Break down fast and are not toxic

Safer from fire

Made from plants and other renewable things

Stay strong and last longer

Old transformer oil must be handled safely. Recycling is good for nature and saves money. Companies clean, filter, and treat old oil to take out bad chemicals like PCBs. Certified recycled oil meets strict rules and works just like new oil.

Recycling transformer oil saves resources and cuts down waste.

Workers watch the oil during cleaning to make sure it is safe. Disposal follows special steps, and companies get papers to show it was done right. On-site recycling lets transformers keep working, so the process is fast. Many companies add oil recycling to their plans to help the environment.

Disposal/Recycling Step | Description |

|---|---|

Filtering and degassing | Takes out water and gases |

Chemical treatment | Removes PCBs and other bad stuff |

Certification | Shows safe disposal or recycling |

On-site recycling | Lets transformers keep running |

Safe disposal and recycling help protect nature and support using things again. Testing oil often and taking care of it keeps transformers working and the earth healthy.

Picking the right size oil-filled transformer keeps power systems safe. You need to think about a few things when choosing the size. Power rating tells you the most power the transformer can give. Voltage rating shows the input and output voltages. Current rating is the highest current it can handle. Temperature rise and cooling decide how much load it can take. Power factor changes the real power sent out. Impedance limits current and affects the load. The type of load changes how well it works. Weather, height, and pollution can make cooling harder. How the transformer is used and if the cooling works well also matter.

Tip: Use this formula to find load capacity: Load Capacity (kVA) = Power (kW) / Power Factor (PF). Always watch for changes in load and check the cooling system.

Both cost and performance are important when picking a transformer. Oil-filled transformers usually cost more than dry-type ones. Bigger transformers and higher ratings make the price go up. Oil, cooling, and safety features like fire protection add to the cost. You also need to pay for oil tests and cleaning over time.

Transformers that are too big waste energy and money.

Transformers that are too small can get too hot and break early.

The right size gives good service and lasts longer.

Factor | Impact on Cost and Performance |

|---|---|

Power Rating | Higher rating increases cost |

Cooling System | Complex systems add expense |

Oil Quality | Better oil raises initial cost |

Safety Features | Fire protection adds to price |

Maintenance Needs | Ongoing costs for oil and parts |

Picking the best oil-filled transformer helps keep power safe and steady. The table below lists what to look for:

Criteria | Importance for Selection |

|---|---|

Cooling Mechanism | Needed for high-power, high-voltage jobs |

Safety & Environment | Requires leak and fire protection |

Maintenance & Costs | Balance upfront and ongoing expenses |

Performance & Capacity | Must match system voltage and load needs |

Installation Site | Outdoor use needs spill containment |

Hot places need strong cooling.

Wet areas need sealed tanks.

Outside sites need spill protection.

Note: Always pick a transformer that fits the power system's needs. Check local rules and plan for future changes.

Oil-filled transformers have many good points. They work better and are smaller than dry-type ones. They make less noise and last longer. They cool down well and can handle heavy loads. It is easier to recycle them and use safe fluids.

Taking care of them keeps them safe and working well. You should check oil levels and temperature a lot. Look for leaks or broken parts. Test and clean the oil on a schedule.

Picking the right transformer depends on how much power you need. Where you put it and how safe it must be also matter. Experts can help you choose the best one for your job.

An oil-filled transformer changes voltage in power systems. It uses oil to cool and insulate its parts. This helps it handle heavy loads and high voltages safely.

Workers should check oil levels and quality every month. They should test for water, acid, and dirt. Regular checks help the transformer last longer and work safely.

Most oil-filled transformers stay outside. They can leak oil or catch fire. Dry-type transformers work better indoors because they do not use oil.

Dirty oil loses its power to cool and insulate. This can cause overheating or electrical faults. Workers must clean or replace the oil to keep the transformer safe.

Eco-friendly oils break down faster and do not harm plants or animals. They lower fire risk and help companies follow safety rules.

Oil Type | Environmental Benefit |

|---|---|

Natural Esters | Biodegradable, non-toxic |

Synthetic Esters | High fire safety |